Environment

Environmentally Friendly • Socially Responsible

Throughout Summitville’s long existence in the extruded quarry tile and brick manufacturing business, dating back to 1912, we have taken pride in the posture that we have assumed with respect to the environment. Our mission statement has not changed: we strive to engage in environmentally responsible practices... from the mining of our raw materials to the manufacture of our products.

To this end, Summitville Tiles, Inc. abides by and/or exceeds all applicable local, state and federal environmental guidelines, rules and regulations at each of its mining and manufacturing facilities. Our mining reclamation record is flawless, with much of the reclaimed mining operations now converted to grazing fields for the champion Angus cattle of Summitcrest Farms. And in our factories, we strive to re-process unused clay and “in-process” clay back into our production to the fullest extent possible. Our fired clay products that are not sold as first quality products are sold as “seconds” and the small percentage of fired waste that remains is ground and used in the construction industry as highway “fill” and/or in other appropriate construction “fill” applications.

Summitville Tiles, Inc. has never been cited for violations of local, state or federal environmental rules or regulations.

Additional indicia of environmentally responsible practices include:

- Summitville Tiles, Inc. has been owned and operated by the Johnson family since 1912 and is, today, the only charter member of the Tile Council of America, the national trade association representing the United States ceramic tile industry. All of the products manufactured by Summitville meet the rigid standards of performance that are required by the TCA certification and as otherwise prescribed the American National Specification Institute (ANSI). Certificates of Master Grade are available for any shipments made out of our factories.

- Summitville Tiles, Inc. is the only American ceramic tile producer that mines its own raw materials on site, and produces a complete line of installation materials. So, there is not only quality assurance from the raw material phase to the installation phase, but there is control over the environmental impact of all these phases of operation.

- In the manufacturing operations of the company, we have engineered systems for reclaiming waste clay so that “scrap clay” can be efficiently recycled back into the production of first quality tile and brick. Clay and shale by-product that is not recycled in the plant is recycled back into the mining reclamation process which enables reclaimed mining areas to be brought back to their original terrain, itself a highly desirable, environmentally favorable outcome.

- The average life cycle of the quarry tile and brick products that are manufactured by Summitville are far greater than carpet, vinyl, wood and other common flooring materials which contributes ultimately to less energy and less waste in disposal of replaced materials.

- Summitville’s diverse line of ceramic products are inherently durable and resistant to bacteria, mold and mildew and denigration by most chemicals. They can be cleaned and maintained without the use of harsh chemicals which contribute to an environmentally sound maintenance record.

- Summitville Tiles, Inc. maintains routine employee information meetings and briefings on working safely with all materials used in the manufacturing process. The company stresses the importance of being environmentally responsible in the handling of all manufacturing materials.

- Above all else, the CEO of Summitville Tiles, Inc. personally oversees the company’s environmental impact policies and procedures, personally inspecting the mines and the manufacturing facilities to ensure that the letter and the spirit of the company’s corporate mission is being adhered to the fullest extent.

Questions and comments relating to this mission statement may be directed to the attention of Mr. David W. Johnson, CEO of Summitville Tiles, Inc. P.O. Box 73, Summitville, Ohio 43962.

---------------------------------------------------------------------------------------------------------------------------------------------------

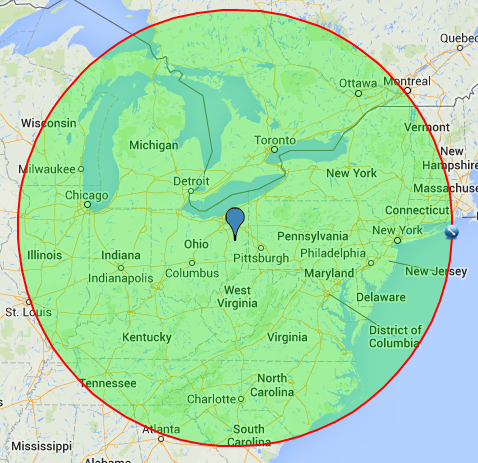

LEED Credit - MR Credit 5: Regional Materials

10% Extracted, Processed, & Manufactured Regionally = 1 point

20% Extracted, Processed, & Manufactured Regionally = 2 points